Bernhard Schulte Shipmanagement (BSM) is expanding its fleet portfolio and has for the first time taken on the technical management of a Floating Storage and Regasification Unit (FSRU). The vessel is managed by Pronav, BSM’s highly specialised Ship Management Centre which exclusively operates large-scale LNG carriers from its Hamburg-based office.

The 2019 built FSRU ‘Turquoise P’, owned by Pardus Energy Ltd., is stationed at the Etki Liman LNG terminal in the Turkish Aegean Sea, near Izmir. It has a length of 294 m and a cargo capacity of 170,000 cbm.

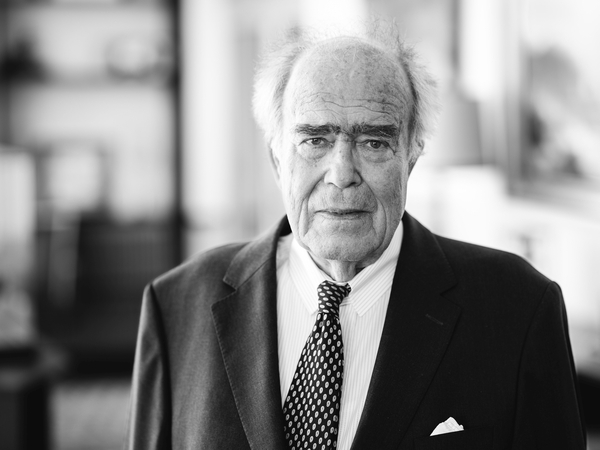

“This is a milestone for Pronav and the entire Schulte Group. We are proud that our many years of expertise in ship management of LNG carriers and our flawless safety record have enabled us to take on the technical management of ‘Turquoise P’,” says Martin Roolvink, Managing Director of Pronav. He emphasises that the LNG segment is subject to the most demanding industry requirements and that the highest safety and quality standards are key in LNG ship management.

FSRUs are ship-based facilities that receive, store, and convert liquefied natural gas back into gaseous natural gas for delivery to shore. The Etki Liman LNG terminal, connected to Türkiye’s national gas grid, is of major importance in supplying energy to the Izmir region, especially during times of peak demand or seasonal fluctuations. The unconditional availability and reliability of the facility is therefore a top priority.

There are currently just over 50 FSRUs in operation worldwide and only very few are managed by third-party ship managers. Pronav is highly recognised by energy majors, LNG charterers and LNG terminals around the world for its operational safety, quality, reliability, and efficiency. Pronav has more than 25 years’ experience in the technical management and crewing of different types of LNG carriers, such as the latest generation equipped with dual-fuel engines (MEGI & X-DF) but also slow-speed diesel with 100% relic plants (Q-Flex) as well as conventional steam vessels (both with Moss-type and membrane tanks).